Manufacturing Unit

Plant And Machinery, Technical Know-how

Utilizing our sophisticated infrastructural facilities & extensive technical expertise, we are capable to execute turn key projects and offer complete solutions for the different requirements of our clients. Given in the table below is a list of plant & machinery installed in our facility that we use in order to deliver quality solutions for welding & cutting consumables. We are engaged in providing welding electrode manufacturing plant, electrode manufacturing plant, welding electrode manufacturing machine, electrode manufacturing machine, welding flux, welding material etc..

Dry Mixer

Dry Mixer machine is used to blend the powders in dry form. Different dry powders in measured quantity are poured to the dry mixing chamber thru a funnel. A ribbon type blade is mounted on a shaft. It is driven by a gear box and motor. the mixing system have reverse and forward rotation of the blade, makes the homogenous dry mix.

Product Details:

- Capacity: 500-1000 kgs

- Brand: Eureka

- Design Type: Standard

- Power: 5 HP & 15 HP

- Shell Height: 1200mm

- Shell Diameter: 620mm & 950mm

Wet Mixer

The dry mixture powder is measured and poured into the drum. Blinding agent in measure quantity is added slowly during rotation of the heavy rollers. These heavy rollers are mounted on a shift. The shift is driven by a gear box and motor. Scrappers are provided to make the mixture uniformly.

Product Details:

- Capacity: 10 kg - 300 kg

- Brand: Eureka

- Design Type: Standard

- Type: Muller Type

- Type of Mixing: Single Roller & Double Roller

- Power: 2HP - 25HP

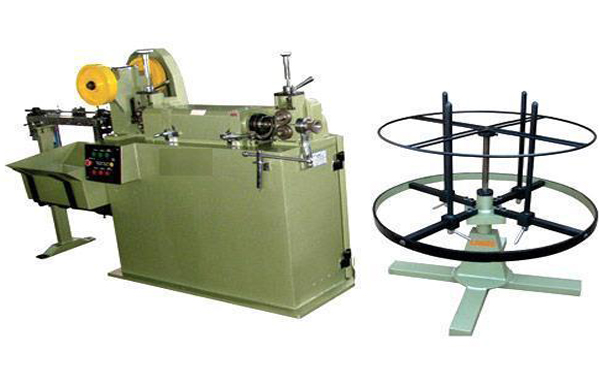

Wire Straightening & Cutting Machine

The drawn coil is loaded on the coil stand. The wire feed through roller and spinner(rotates at high speed) get straightened and passing to cutting area. The straightened wire cut by a cam operator mechanism. The spring operated scaling bar used to maintain the length of the wire during cutting. The length of the cut wire can be adjusted easily on the scaling bar. Cut wires are collected by a tray kept underneath. This wires are collected form the wire tray stacked on a cut wire stand. For different diameter of wire.

Product Details:

- Cutting Speed: 120 - 200 Cuts/min

- Power: 6HP - 11 HP

- Feed Roller: 4 Nos. dia 70 4 Nos. dia 100

- Spinner Die: Tungsten Carbide

- Coil Stand Capacity: 300kg

- Top Plate Thickness: 25mm & 40 mm

Extrusion Plant Conveyor

Dedicated to cater to the specific requirements of clients efficiently, we are instrumental in manufacturing and exporting Extrusion Plant Conveyor. Widely used for conveying diverse products, these conveyors are broadly used in food, pharmaceutical and chemical industries. Manufactured from tested quality metals, these conveyors are offered to clients in diverse technical specifications as per their requirements.

Product Details:

- Automatic Grade: Automatic

- Production Capacity: 500-1000 KG/HR, 1000-1500 KG/HR

- Raw Material Processed: Flux

- Nominal Press Force (Kilo Newton): 2000-2500